ACC Blocks

AAC Blocks

Autoclaved Aerated Concrete (AAC) blocks are innovative, lightweight building materials created through a precise reaction between aluminum powder and a well-balanced mix of lime, cement, and fly ash or sand. With a proven track record spanning over 80 years, AAC blocks are celebrated for their:

- Lightweight and Durable Nature.

- Energy Efficiency.

- Eco-Friendly Properties.

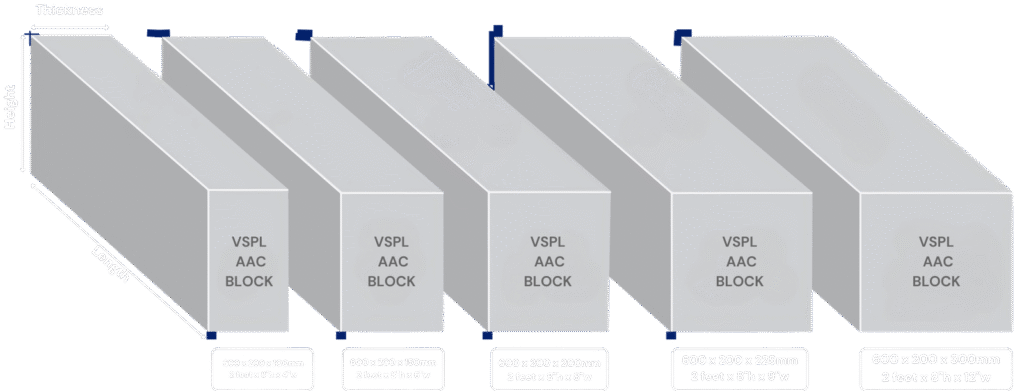

Standard Sizes of AAC Blocks

VSPL AAC Blocks Dimension

LENGTH (mm)

HEIGHT (mm)

THICKNESS (mm)

600 (2 ft)

200 (8")

100 (4")

600 (2 ft)

200 (8")

150 (6")

600 (2 ft)

200 (8")

200 (8")

600 (2 ft)

200 (8")

225 (9")

600 (2 ft)

200 (8")

300 (12")

- Length - 600 mm

- Height - 200 mm

- Thickness/Width Options - 50 mm, 75 mm, 100 mm, 150 mm, 200 mm, 225 mm, 300 mm